If you’re a waterfowl hunter, then there’s no question you’ve heard of Migra Ammunitions company. The edgy, forward-thinking company was founded in 2016 by Drew McIntosh. Drew’s story of building one of the most technologically advanced gun/hunting-industry businesses truly did begin with him handloading shotshells in his garage.

As you’ll learn during this exclusive interview, Drew’s primary motivation for founding Migra was not financial gain, and this principle has guided the company's now-legendary operations. There’s no question at all that Drew McIntosh and his elite team at Migra are doing it the flyway.

Hook & Barrel (HB): Before you started Migra, what was your main occupation?

Drew McIntosh (DM): I ran a small international travel company for hunting and fishing called Rod and Gun Travel Co. At the same time, I worked full-time as a material handling sales manager. During this period, I started learning about shotgun shells because of unusual circumstances.

I was often in and out of warehouses, and one day I came across a group of guys loading exotic-type shotgun shells. Out of my own interest in waterfowl hunting, that’s when I decided that I’d like to learn how to do it, and I was interested in making something better. They taught me the basics of handloading shotshells.

HB: Most people don’t just casually start an ammo company. What made you decide to start your own?

DM: I was booking hunts for outfitters, booking clients, including some of my industrial clients. We got frustrated with the ammo available at the time. I met some guys (previously mentioned) who were loading exotic loads — dragon breath/exotic defense loads, for example — and it inspired me.

I went back to them with my idea and the goal was to make a better-performing, non-toxic steel shot.

In the moment, we started researching other manufacturers' products and playing around with different materials/components from around the world. I realized I could develop a new load with all-new technology for shotgun shells, and I realized the market was behind on technology.

A better load was obtainable utilizing my stacked design idea (which was not yet patented). I was improving the loads and patterns, and I was the only one doing it.

I was handloading anywhere I could — mom’s garage, the warehouse or even my apartment (sometimes) — and throughout the season, clients would come by to pick up ammo and leave money in flower pots. I challenged my friends who own an outfitter in Texas/Oklahoma to hunt with it for a season.

With a good mix of clients, young and older, I knew it would be great feedback. After that season, we knew I had something that was exhaustively better than the marketplace could offer, if I could manufacture it at a higher scale.

The Migra Difference

HB: What sets Migra apart from other brands?

DM: We have developed a patented technology no one else has, where a percentage of larger shot is loaded on top of a percentage of smaller shot with custom components — a stacked load.

The specific ammo design, with custom components and drafting concept, reduces pattern friction and concentrates shot patterns. The most notable difference in the market is that the method gives us 20+% improved pattern retention at longer distances.

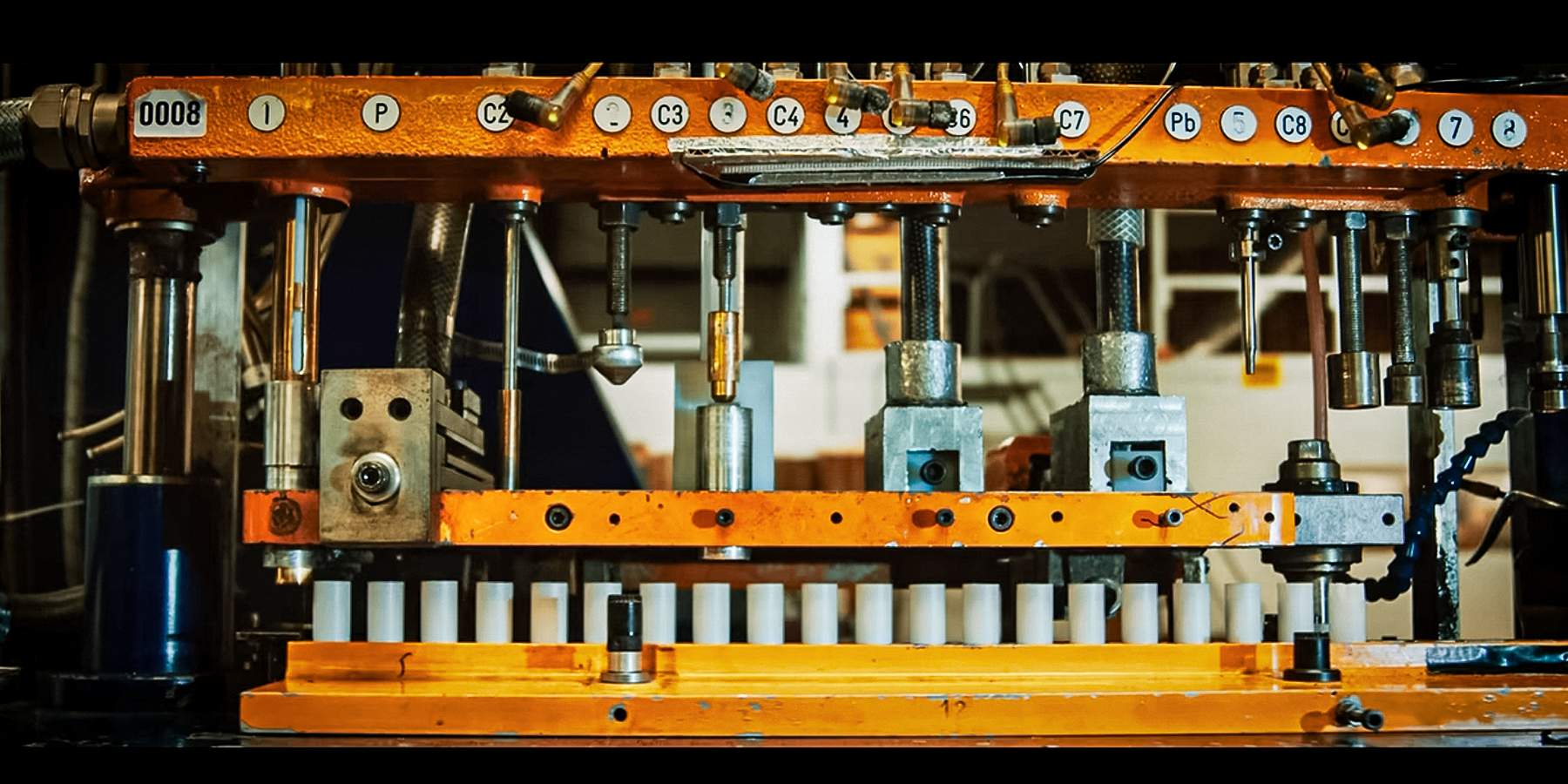

Migra was the first to introduce this in the market, and now you see other manufacturers produce different versions. We have also vertically integrated ourselves with custom components and we specifically manufacture in small batches.

We have invested in the newest machine advancements in the country, specifically designed for our patented stacked load. We developed new technology in our new LFW, low-friction wad, which helps decrease pressures in the barrel by decreasing friction between pellets, giving 5% more concentrated shot patterns than our original concept design from 2019.

Breaking Into a Competitive Market

HB: Who helped you break into the business?

DM: In development, it was Jay Menefe who showed me that we could manufacture on machinery for the first time, and that's when I knew I could scale the company and improve my designs.

I met John Faber, who was the first person in the shooting industry who gave me confidence after developing the MIGRA brand that we could bring it to the retailers. I then met Jim Nasim, who helped me secure funding and was the first investor in MIGRA. We met at a Waffle House one morning and agreed on a $1.2 million deal.

Q-Tip (David Yanello), who is my best friend and went everywhere with me, helped me stay grounded and focused on business. My attorney, Konstantine Diamaduros, was instrumental in helping me draft patents and contracts. I was his first client.

I met Andy Trann at SHOT Show — he was instrumental in marketing MIGRA at that time. We pioneered ammunition marketing on social media, nobody was doing it back then.

In 2023, I met Mark Regalbuto through a mutual friend, who wanted to join the brand, and he came on as the CEO/partner to help scale the company to where it is today.

HB: What was your initial investment to get Migra off the ground, and what was a surprising expense in the early days?

DM: Initially, I invested my life savings and drove around in a truck with no AC — I was all in! A big challenge was the shortage of powder right before COVID.

During that time the price of powder nearly tripled, and we had to figure out how to manufacture at scale, which meant pumping money in order to keep up with market demand.

It was an expensive, but smart decision, and changed the trajectory of the company as we were able to produce when nobody else could, but it almost broke us.

The COVID Era Was a Blessing in Disguise for Migra

HB: What was Migra’s “lucky break” in the supply chain or production process?

COVID was both a negative and a positive. While it hurt in some ways, it also opened us up to all channels in the retail space, as everyone was desperate for product. We made the decision to invest everything we had — no paychecks for a year or two — just to buy as much powder as we could.

Even with the price increase, we bought all we could. The tides turned as everything we made sold immediately. Our first big win on a national scale was with Sportsman’s Warehouse, and from there, it opened up our relevance and seeded us in other major chains and retailers.

COVID was a blessing in disguise, as it catapulted us to grow at 300% annually during those years.

The Early Days and Migra's Marketing Strategy

HB: Tell us about the Migra name and logo

DM: The name Migra came after a lot of thought and study. I was obsessed with it, and one day, while having a beer with Konstantine on a Thursday, I wrote it down on a napkin. It clicked right then.

Migra reflects the idea of migration, like how ducks migrate, and I knew it would connect with duck hunters. I wanted clean and simple branding.

As for the logo, I was working out late one night in a gym, and I saw a new “M” design on some equipment. The vision clicked, and I thought it could represent the outward legs of a duck. I worked with an eager graphic designer to make it a reality late one night, and that’s how the logo was born.

HB: What did you learn from your early days?

DM: Starting a company is one thing but building a national brand is a bigger mountain to climb. Everything was harder than I thought it would be and I had to wear many different hats to make the business work.

You had to go after what you wanted, so John, Jim and I packed the truck with ammo and a new rep group and personally visited every store that was waterfowl-centric to where we wanted to strategically place our brand. We learned that the market was starved for the new brand with new technology to revamp the marketplace for shotgun ammunition.

That road trip was the start of our dealer network and we did it ourselves to make it happen. I had to personally build myself up mentally and emotionally to handle it; the brand was growing so fast, it was outgrowing my skill sets and I had to learn fast.

HB: What has been key to successful marketing?

DM: We had a brand and product vision for the marketing strategy that was so new it had never been done. We knew we didn't have the budget, so we went against the industry norm and went after social media mediums, starting the marketing campaign just on Instagram.

I worked with Andy Trann to help implement and bring the vision into a marketing plan. I personally studied Russel Branson, who made mundane industries into exciting products, and that is what we wanted to do with our ammo. Social media was the future, and we launched on Instagram with a $20,000 budget.

We facilitated collaborations with ambassadors and sent mysterious white, blank boxes full of white shotgun shells to photographers, outfitters and influential people.

We heavily focused on the organic growth side of things — talking to people and building a team, to building a solid community around the brand. We had to do it all without paid advertising because we couldn't promote ammo directly on social media.

That grassroots effort is still a big part of how we operate today to build an amazing community around the brand.

HB: What’s a money-losing experiment that taught you something valuable?

DM: A big mistake was giving a supplier a large deposit without a solid contract in place. The lesson: Build trust and relationships with those you work with, but always verify who you’re doing business with.

Trust comes over time, but verifying is crucial. The small things also add up—product waste and misshipments, shipping too much or not enough of product.

Ammunition is a cash-up-front business, and if you don't have it, you're not getting anything. Because of the politics in banking, we had to get creative on cash flow strategies and financing. We reinvested year over year into ourselves, total reinvestment.

The Future of the Ammo Industry

HB: Where do you see the ammo industry heading in the next 5 to 10 years?

DM: The industry is stagnant and consolidating — companies are buying out other companies instead of developing new tech. We focus on innovation — pushing the limits with new designs and materials to stay ahead.

We’re recruiting top talent and exploring new ways to make products that enhance the shooting experience. We are poised for the future as our entire brand is to make steel shot more lethal, and this is combating the rising cost of non-toxic materials such as bismuth and tungsten.

With a greater investment into R&D, new tech and custom machinery, we have fine-tuned our patented technology in steel shot to the highest performance level ever seen in the industry.